Airplane engines are complex systems designed to provide the necessary thrust to propel an aircraft forward. There are several types of airplane engines, each serving different kinds of aircraft.

Jet engines are the most common for commercial airliners and military aircraft. They work on the principle of jet propulsion, using air compression and combustion to create thrust. There are several types of jet engines:

Piston Engines (Reciprocating Engines)

Piston engines are similar to those used in cars but are specially designed for aviation. They are typically used in smaller planes, such as general aviation and training aircraft. These engines work by using the combustion of fuel to move pistons, which in turn rotate a propeller to generate thrust.

- In-line Engines: Cylinders are arranged in a line, and they tend to be streamlined, making them suitable for aircraft with smaller frontal areas.

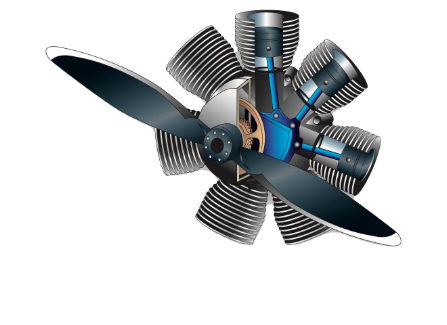

- Radial Engines: Cylinders are arranged in a circle around a central crankshaft. These were common in World War II-era aircraft.

Propfan Engines

These are hybrid engines that combine features of both turboprop and turbofan engines. They are designed for high-speed flight while maintaining fuel efficiency.

Jet Engines

- Turbojet: The simplest type of jet engine, used in early jet aircraft. It compresses air, mixes it with fuel, and ignites it to produce a high-velocity exhaust stream.

- Turbofan: The most common engine for modern airliners, featuring a large fan at the front. The fan moves a large amount of air, making it quieter and more efficient at lower speeds.

- Turboprop: A jet engine that drives a propeller, used in regional and cargo aircraft. These engines are fuel-efficient at lower speeds and altitudes.

- Turboshaft: Commonly used in helicopters, this type powers a rotor instead of producing direct thrust.

Types of Piston Engines

Horizontally Opposed Engines:

- Most common in modern light aircraft.

- The most popular reciprocating engines used on smaller aircraft.

- These engines always have an even number of cylinders, with pairs of cylinders on opposite sides of the crankshaft. The cylinder on one side of the crankcase “opposes” a cylinder on the other side.

- The majority of these engines are air cooled and usually are mounted in a horizontal position when installed on fixed-wing airplanes.

- Opposed-type engines have high power-to-weight ratios because they have a comparatively small, lightweight crankcase.

- In addition, the compact cylinder arrangement reduces the engine’s frontal area and allows a streamlined installation that minimizes aerodynamic drag.

- Provides a compact, balanced, and low-vibration engine design.

- Example: Lycoming O-320, commonly found in aircraft like the Cessna 172.

Radial Engines:

- Cylinders are arranged in a circular pattern around a central crankshaft.

- Widely used in early and mid-20th-century aircraft, especially during WWII.

- Known for their durability and ability to operate at low RPMs.

- Example: Pratt & Whitney R-2800 Double Wasp, used in aircraft like the P-47 Thunderbolt.

In-line Engines:

- Cylinders are arranged in a single line or a “V” shape.

- They are streamlined and reduce frontal drag, making them suitable for certain high-performance aircraft.

- Example: Rolls-Royce Merlin, used in the famous Supermarine Spitfire.

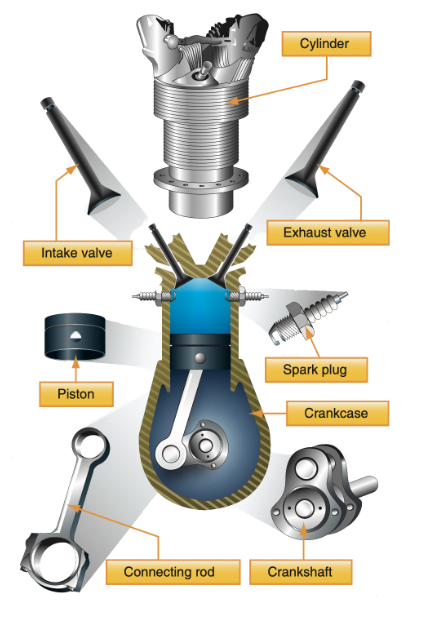

Components of a Piston Engine

- Cylinders: Where fuel-air mixture combustion occurs. Most airplane piston engines have 4 to 6 cylinders, though some have more.

- Pistons: Move within the cylinders, driven by combustion to turn the crankshaft.

- Valves and Camshaft: Control the intake of the air-fuel mixture and the exhaust of gases.

- Crankshaft: Converts the up-and-down motion of the pistons into rotational motion to drive the propeller.

- Spark plugs The spark plug are responsible for igniting the fuel / air mixture

- Propeller: Directly driven by the crankshaft to create thrust, propelling the aircraft forward.

- Magnetos and Ignition System: Generate the electrical spark to ignite the air-fuel mixture. Aircraft typically have dual magnetos for redundancy and reliability.

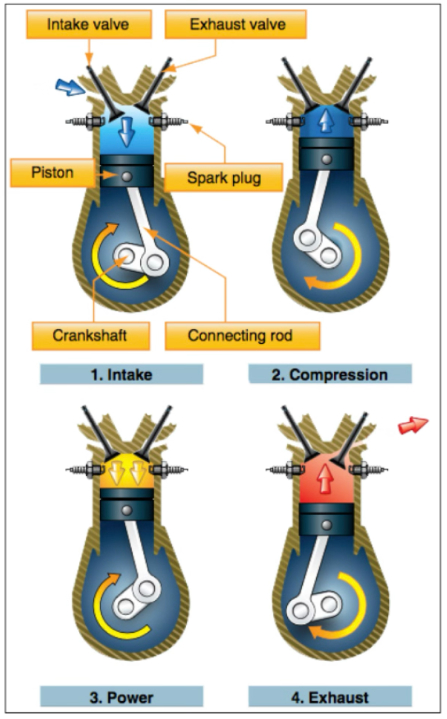

Working Principle of a Piston Engine

Piston engines operate using the four-stroke cycle, also known as the Otto cycle:

- Intake Stroke: The intake valve opens, and the piston moves down, drawing in a fuel-air mixture into the cylinder.

- Compression Stroke: The intake valve closes, and the piston moves up, compressing the fuel-air mixture.

- Power Stroke: A spark plug ignites the compressed mixture, causing an explosion that forces the piston down, creating power.

- Exhaust Stroke: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder.

This continuous process drives the crankshaft and propeller, generating the necessary thrust to move the aircraft.

As a memory aid for the four strokes think..

- Suck (Intake) – down stroke – fuel / air mixture goes into cylinder

- Squeeze (Compression) – up stroke – fuel / air mixture is compressed

- Bang (Power stroke) – spark plug ignites fuel / air mixture

- Blow (Exhaust) – up stroke gas is pushed out

Performance Characteristics

- Fuel Efficiency: Piston engines are generally more fuel-efficient than jet engines at lower speeds and altitudes, making them ideal for light aircraft.

- Altitude and Speed Limits: Piston engines typically perform best at lower altitudes (below 15,000 feet) and slower speeds (under 300 mph). Their performance can decline at higher altitudes unless turbocharged.

- Cooling: Piston engines are either air-cooled or liquid-cooled. Air-cooled engines are more common in general aviation due to their simplicity, but liquid-cooled engines provide more consistent cooling, especially in extreme conditions.

Turbocharged and Supercharged Engines

To maintain performance at higher altitudes, some piston engines are turbocharged or supercharged:

- Turbocharged: Uses exhaust gases to drive a turbine, which compresses the incoming air, allowing the engine to generate more power at higher altitudes where the air is thinner.

- Supercharged: Mechanically driven by the engine’s crankshaft, this device compresses the air, but it tends to be less efficient than turbocharging at higher altitudes.

Common Airplane Piston Engines

- Lycoming Engines:

- Popular for light aircraft, Lycoming engines are known for their reliability and are used in planes like the Cessna 172 and Piper Cherokee.

- Example: Lycoming O-360, a four-cylinder, horizontally opposed engine.

- Continental Motors Engines:

- Another major manufacturer of piston aircraft engines, used in small general aviation aircraft.

- Example: Continental O-200, which powered aircraft like the Cessna 150.

- Rotax Engines:

- These engines are popular in ultralight and light-sport aircraft due to their lightweight design and fuel efficiency.

- Example: Rotax 912, commonly found in smaller, experimental, and light-sport aircraft.

Advantages of Piston Engines:

- Fuel Efficiency at Low Speeds: Ideal for short-haul flights and lower cruising altitudes.

- Cost: Less expensive to build and maintain compared to jet engines.

- Reliability: Well-established technology with high reliability for small aircraft.

Disadvantages:

- Performance at High Altitudes: Piston engines are less efficient at high altitudes due to thinner air unless turbocharged.

- Noise and Vibration: Piston engines are generally noisier and produce more vibration than turbine engines.

- Power Output: Limited power compared to jet engines, making them unsuitable for larger aircraft.

In summary, piston engines are fundamental to general aviation, offering a balance of simplicity, fuel efficiency, and reliability, making them ideal for smaller aircraft that operate at lower altitudes.